HDPE Geomembrane Protection

1. Using HDPE geomembrane for ponds, lakes and wastewater tanks:

– Places containing a lot of gravel, crushed stone and under the impact of rolling rocks, collisions of floating objects will easily cause HDPE membranes to be punctured and damaged. Therefore, it is necessary to design a protective cover to protect membranes from such effects.

– Protective cover has the effect of protecting membranes from short-term mechanical impacts such as punctures caused by sharp objects, construction loads and long-term impacts that cause stretching, reducing durability during use.

– The forms of protective cover are selected based on the structure, geological features of the building and the type of impact load.

2. Protection below membrane:

– Protection with geotextile: Apply when the soil does not have gravel, foreign objects that are potentially harmful to HDPE geomembrane.

– Protection with geotextile combination: In case the foundation has many cracks, many sharp objects, the foundation is porous and hollow material, spread a layer of geotextile and then pour sand to form a protective layer under the membrane.

3. Protection above membrane:

– Protection with top soil layer: Using soil cover to protect the top surface of the geomembrane, the thickness of this soil cover must be calculated for each specific condition to ensure sustainability and stability during the exploitation and operation process.

– Protection with reinforced concrete: designed into each cell, the bottom is covered with a layer of geotextile padding.

– Protect other materials such as Geocell, Geoweb with HDPE material that has been poured with stone or concrete.

HDPE Geomembrane Combination Forms

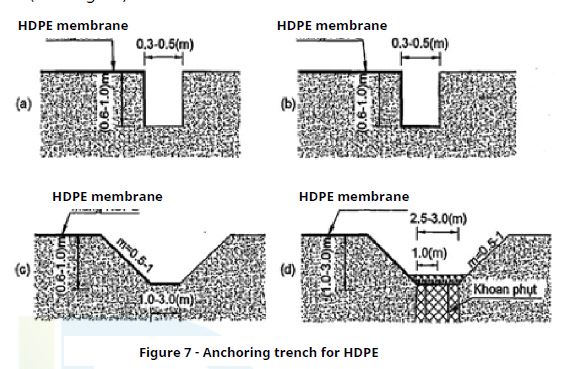

1. Anchoring trench structure (pinning geomembrane):

a) Layout forms: (as in figure)

b) Structure requirements:

– The textile in the anchoring trench must not have welds, must not have irregular shapes to avoid damage to the material.

– The soil poured into the anchoring trench after installing the membrane must be tightly packed with K > 0.95 (the filling must be carried out immediately after the geotextile is laid).

2. Connecting the membrane with other structures:

2.1 Connecting geomembrane with concrete, brick, and stone structures:

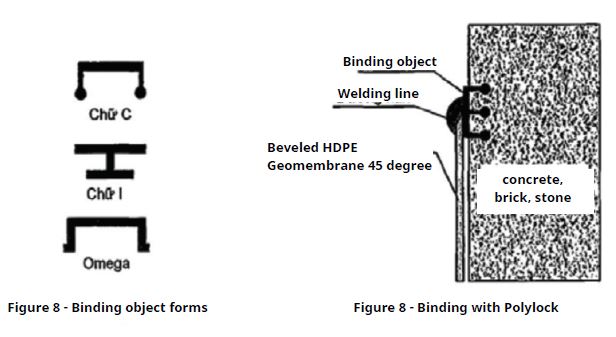

a) Connecting with a binding object:

– Binding objects are prefabricated polymer parts, having the same composition as the geomembrane, diverse designs (I, C, E, Omega) and different sizes:

– Binding objects are installed simultaneously during the construction of concrete, brick and stone structures such as polylock attached to reinforcement or formwork when pouring concrete.

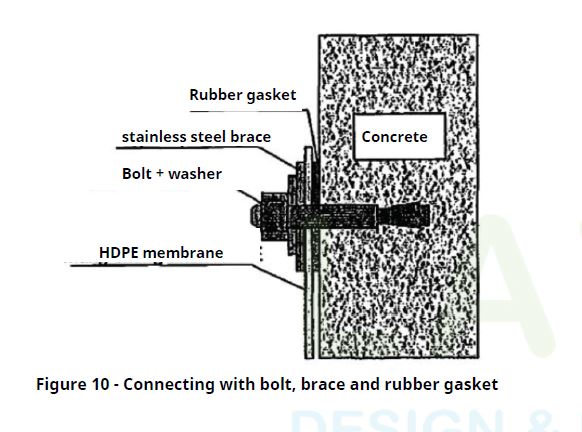

b) Connecting with bolts, braces and rubber gaskets:

– Rubber gaskets are made with components suitable for waterproofing purposes: for waterproofing of waste storage facilities and for waterproofing reservoirs, Neoprene or Nitrine rubber gaskets should be used. For domestic water tanks, the additive component of the rubber gasket must not contain harmful chemicals.

– Braces, bolts, washers should be made of stainless steel.

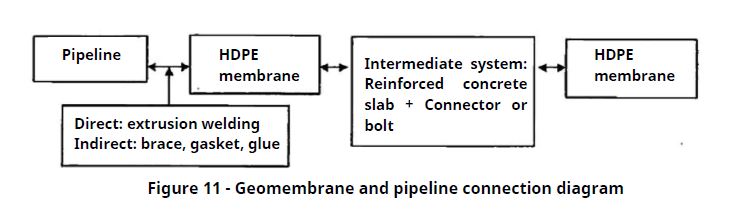

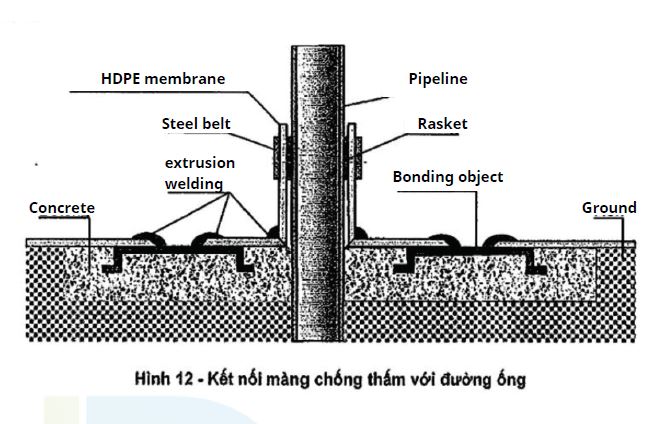

2.2 Connecting the geomembrane with pipeline:

a) Geomembrane and pipeline connection diagram:

b) Components for connecting membranes to pipes made of various materials (steel, concrete, plastic) include:

- Số 28, Tổ 4, Ấp 3, Xã Lương Bình, Huyện Bến Lức, Tỉnh Long An, Vietnam

-

Tax Number

1101794801

Contact Us

- +84 937715638

-

090 818 3628

090 818 9628

093 771 5638 - info@KietKiet.com